Next Floor

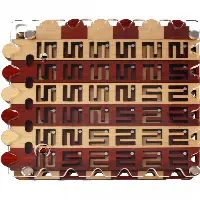

Next Floor is a marble maze. Whereas regular mazes have explicit walls, the walls of Next Floor are implicit. The marble follows trenches in both the floor and the ceiling of a level. The marble stops only if there is a trench end at both floor and ceiling. The marble changes levels through big holes in the floors and ceilings. The marble starts from the center position at the bottom (blue) floor. The goal is to get it out from the red top floor. This 7x7x4 maze is quite complicated, as there are quite a few T junctions in all orientations, where the central leg of the T goes towards the exit. It takes dexterity to manoeuvre the marble to that central leg.

The puzzle was built by using a special embedding technique. First the five floors were 3D-printed in five colors. Then a 3D-print in anthracite was started for the four columns at the corners. The printing of the columns was halted for each floor, the prefab floor was inserted, and the printing was continued. The result is a very solid puzzle.

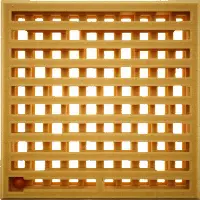

The puzzle has been mass-produced as laser-cut wooden puzzle by LaserExact and Bits&Pieces. However, those productions have halted already many years ago.

The puzzle took 18 hours to 3D print on a Dutchy 3D printer. 51 meter of 1.75-mm PLA filament was used to print it. The puzzle weighs 153 grams.

Oskar van Deventer has created many different puzzles including his brand of Oskar Puzzles which are mechanical puzzles and objects that can only exist thanks to 3D printing technology. Since 1978, he has been creating hundreds of mechanical puzzles, making him one of the world's most prolific designers. Several of his innovative designs are commercially available..

The puzzle was built by using a special embedding technique. First the five floors were 3D-printed in five colors. Then a 3D-print in anthracite was started for the four columns at the corners. The printing of the columns was halted for each floor, the prefab floor was inserted, and the printing was continued. The result is a very solid puzzle.

The puzzle has been mass-produced as laser-cut wooden puzzle by LaserExact and Bits&Pieces. However, those productions have halted already many years ago.

The puzzle took 18 hours to 3D print on a Dutchy 3D printer. 51 meter of 1.75-mm PLA filament was used to print it. The puzzle weighs 153 grams.

Oskar van Deventer has created many different puzzles including his brand of Oskar Puzzles which are mechanical puzzles and objects that can only exist thanks to 3D printing technology. Since 1978, he has been creating hundreds of mechanical puzzles, making him one of the world's most prolific designers. Several of his innovative designs are commercially available..

$42.48